Supply High Collocation Barrier Film Machine

$1500000-2000000 /set

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,EXW |

| Min. Order: | 1 set |

| Transportation: | Ocean,Land |

| Port: | CHINA |

$1500000-2000000 /set

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,EXW |

| Min. Order: | 1 set |

| Transportation: | Ocean,Land |

| Port: | CHINA |

Application: Film

Screw Design: Single-Screw

Screw Material: 38crmoala

Screw Diameter (mm): 80

Marketing Type: Ordinary Product

Core Components: Bearing

Plastic Processed: PE, PP, EVA, HDPE/PP, Lldpe, LDPE

Condition: New

Screw L/D Ratio: 34:1

Showroom Location: Turkey, United States, Italy, Germany, Viet Nam, Philippines, Indonesia, Pakistan, India, Mexico, Thailand, Bangladesh, Nigeria, Japan, Malaysia

Brand Name: SIMCHENG

Warranty: 1 Year

Key Selling Points: High Safety Level, High productivity, energy save

Applicable Industries: Manufacturing Plant

Video Outgoing-inspection: Provided

Machinery Test Report: Provided

Warranty Of Core Components: 1 Year

Name: High Collocation Barrier Film Machine Thickness Line

Screw Speed (rpm): 93 rpm

Place Of Origin: Guangdong, China

Weight: 500 KG

| Selling Units | : | set |

The file is encrypted. Please fill in the following information to continue accessing it

Elevate Your Packaging with Our Advanced Barrier Film Line

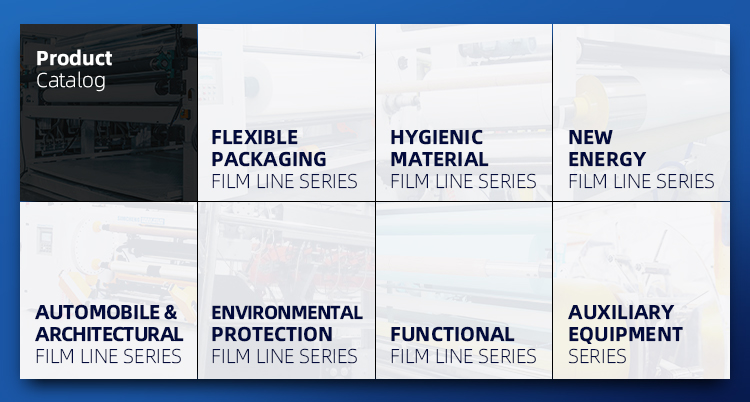

Our barrier film machine is designed to deliver excellent barrier properties, ensuring optimal product protection and longer shelf life. Ideal for various packaging applications, including Flexible Packaging Cast Film Line, the machine focuses on precision and efficiency to produce high-quality cast films.

This machine features a robust screw design that excels in mixing and plasticizing polymers, resulting in superior film performance. The integrated fine filter system ensures clear and consistent film quality. Whether you're crafting Sanitary Cast Film Machine outputs or standard films, the automatic T-die system, equipped with an online thickness gauge, helps achieve precise film thickness, reducing waste and optimizing material usage.

For better film stability, the machine includes double cavity negative pressure and electrostatic edge fixing devices. The high-speed, thin-walled cooling roller aids in consistent film formation, while a special tempering device enhances film stiffness and rigidity, making it suitable for a Hygienic Packing Film Line.

Our machine also includes automatic tension control for smooth winding, and the rotary disc double-station winder efficiently handles large roll diameters. The PLC-based automatic control system, combined with a user-friendly interface, simplifies operation and monitoring, which is vital for all Sanitary Cast Film Line.

Whether you need friction or clearance winding, our machine is adaptable to your specific packaging needs.

Key Features:

Superior barrier properties for longer product life

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.