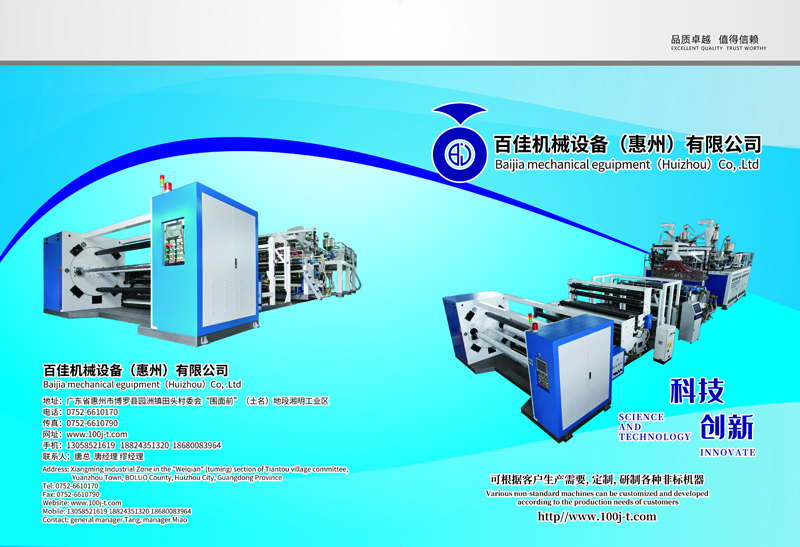

Hot sale CPP packaiging film machine

$900000-1200000 /set

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,EXW |

| Min. Order: | 1 set |

| Transportation: | Ocean,Land |

| Port: | CHINA |

$900000-1200000 /set

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,EXW |

| Min. Order: | 1 set |

| Transportation: | Ocean,Land |

| Port: | CHINA |

Application: Film

Screw Design: Single-Screw

Screw Material: 38crmoala

Screw Diameter (mm): 75

Marketing Type: Ordinary Product

Core Components: Bearing

Plastic Processed: Eva

Condition: New

Screw L/D Ratio: 34:1

Showroom Location: Turkey, United States, Viet Nam, Philippines, Indonesia, Pakistan, India, Mexico, Russia, Thailand, Nigeria, Uzbekistan, Malaysia

Warranty: 1 Year

Key Selling Points: High Productivity,energy save

Applicable Industries: Manufacturing Plant

Video Outgoing-inspection: Provided

Machinery Test Report: Provided

Warranty Of Core Components: 1 Year

After-sales Service Provided: Video Technical Support, Free Spare Parts, Field Installation, Commissioning And Training, Field Maintenance And Repair Service, Online Support

After Warranty Service: Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service

Local Service Location: Egypt, Turkey, United States, Viet Nam, Philippines, Indonesia, Pakistan, India, Mexico, Russia, Thailand, Japan, Malaysia, Bangladesh, Nigeria, Uzbekistan

Screw Speed (rpm): 93 rpm

Place Of Origin: Guangdong, China

Brand Name: Bai Jia

| Selling Units | : | set |

The file is encrypted. Please fill in the following information to continue accessing it

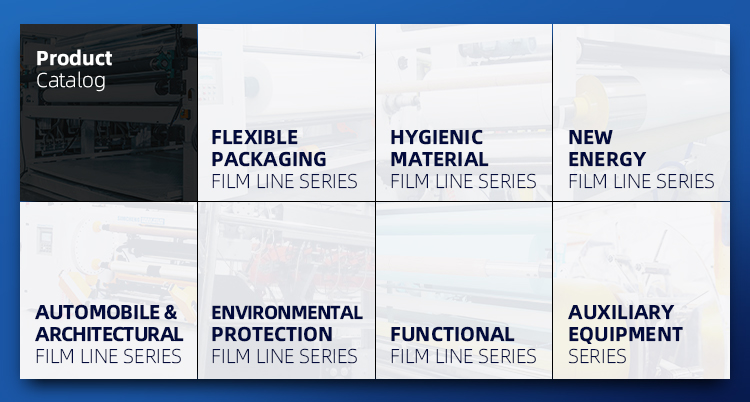

Optimize your film production line with the Hot Sale CPP Packaging Film Machine, engineered to deliver superior Cast Polypropylene films tailored for a range of packaging requirements.

Precision Engineered for Quality:

A single screw extruder, complete with ceramic heating and air cooling, ensures exact temperature regulation and high material quality to maintain film uniformity.

Maximize Uptime, Reduce Delays:

Dual hydraulic network changers streamline transitions, boosting operational efficiency while curbing downtime.

Refined Film Texture and Cooling:

Large rollers produce enhanced embossing, paired with effective cooling systems for impeccable film creation.

Synchronized Production:

SEW servo motors along the production line secure speed continuity, pivotal for film consistency and smooth workflow.

Optimal Film Dimensionality:

An aluminum cooling apparatus reduces shrinkage, locking in film size precision.

The automated unwinding mechanism enhances ease of use, contributing to process simplification.

Streamlined Operational Control:

A PLC system, complemented by a user-friendly MMI, allows for straightforward adjustments and real-time production tracking.

Invest in the Hot Sale CPP Packaging Film Machine for steadfast CPP film production that promises quality, efficiency, and a user-centric experience—a strategic acquisition for forward-thinking manufacturers.

FAQ

FAQ

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.