Best Sale Cast Cpp Film Line

$900000-1200000 /set

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,EXW |

| Min. Order: | 1 set |

| Transportation: | Ocean,Land |

| Port: | China |

$900000-1200000 /set

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,EXW |

| Min. Order: | 1 set |

| Transportation: | Ocean,Land |

| Port: | China |

Application: Film

Screw Design: Single-Screw

Place Of Origin: China

Marketing Type: Ordinary Product

Core Components: Bearing

Plastic Processed: PP, EVA, HDPE/PP, PE/PP, Lldpe, LDPE

Condition: New

Showroom Location: Turkey, United States, Viet Nam, Philippines, Indonesia, Pakistan, India, Mexico, Russia, Thailand, Bangladesh, Nigeria, Malaysia

Warranty: 1 Year

Key Selling Points: High Productivity, energy save

Applicable Industries: Manufacturing Plant

Video Outgoing-inspection: Provided

Machinery Test Report: Provided

Warranty Of Core Components: 1 Year

Name: Cpp Film Line Multi-Layer Co-Extrusion Film Machine Cast Film Line

Screw Speed (rpm): 93 rpm

Weight: 500 KG

| Selling Units | : | set |

The file is encrypted. Please fill in the following information to continue accessing it

Elevate Your Packaging with Our High-Performance Cast CPP Film Line

Our Cast CPP Film Line offers a reliable solution for producing premium multi-layer co-extruded films, perfect for a variety of applications, including flexible packaging cast film lines. Designed for speed, precision, and versatility, this machine ensures outstanding film quality and efficiency.

This line features advanced technology, including a durable screw structure that promotes excellent mixing and plasticizing for consistent film properties. The duplex station hydraulic screen changer facilitates quick and smooth mesh changes without interrupting production. Whether you’re producing Sanitary Cast Film Machine outputs or other specialized films, the automatic T-die system paired with an online thickness gauge guarantees precise film thickness.

The line is equipped with PLC automatic control and a user-friendly interface for seamless operation. It also supports both friction and gap winding, providing versatility whether you’re producing sanitary cast film lines or other types of films.

Key Features:

Multi-layer co-extrusion for versatile film production

High-speed and efficient operation

Precise film thickness control

Enhanced film stability and quality

Cost-effective on-line edge material recycling

User-friendly PLC control

Versatile winding options

Experience the reliability and efficiency of our Cast CPP Film Line. Contact us today to discuss your specific packaging or Flexible Packaging Cast Film Line needs.

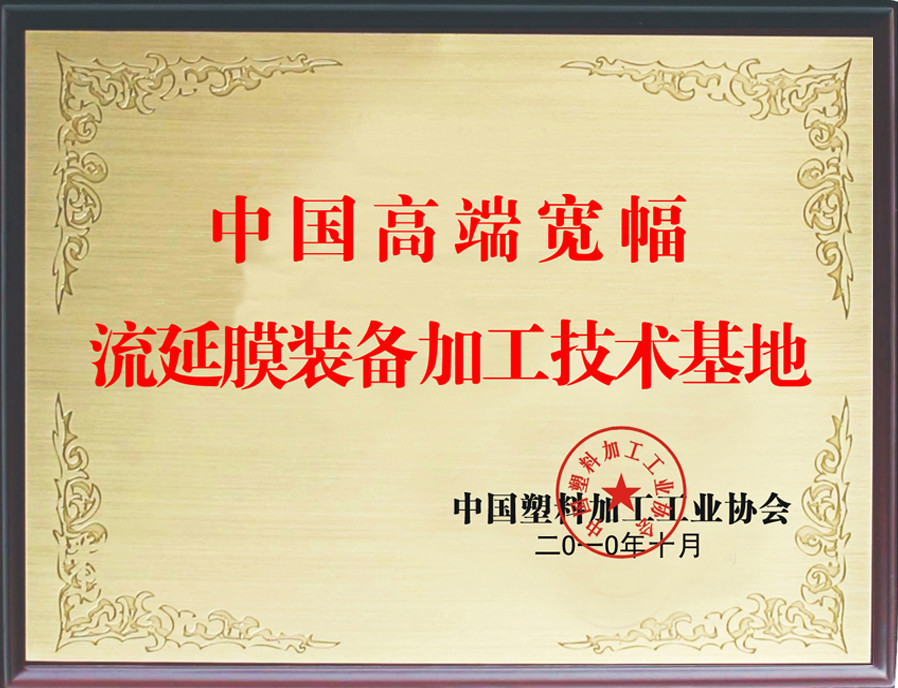

Certifications

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.